I wrote about Kintsugi and its philosophical meaning, but I was always curious about actually trying to practice the art. And for that, I signed up for the mini Kintsugi class in Sydney. It’s a family-owned business with a Kintsugi master Jun and his wife Hitomi who ran our class.

How Did Kintsugi Start?

Kintsugi’s claim to fame dates back to the 15th century when the governor of Yoshimasa Ashikaga broke his favourite tea cup. Unlike mere mortals who would get a new cup and move on with their life, the governor had the power to get the same design cup from China. He sent his envoys to Porcelain merchants searching for a replacement.

Unfortunately, porcelain craftsmen had difficulties with sourcing materials or lacked skills and an identical cup could not be produced. Instead, the crafty merchants arranged to fix the cup with metal wire making it look like it was stapled together. The governor was not impressed with the fit and refused the cup. Ironically it is now considered a national treasure that goes on public display only a couple of times a year.

The governor took the matter into his capable hands and ordered the finest craftsmen to come up with an alternative. The solution was to join broken tea cup pieces with a mixture of plant resin and gold powder emphasising the brokenness. And this is how Kintsugi, the art of mending pottery with golden paste began its life.

Kintsugi Process Step-by-Step

The traditional way of using plant resin can take months to finish but it was still worth the wait as porcelain was expensive in 15th century Japan. This method is still used however it is a long and expensive process which explains the cost of Kintsugi pieces that you see online.

In the class, we used an “express method” using modern materials such as epoxy which is unlike tree sap takes minutes to harden. This is a secret Know-How process that Jun and Hitomi developed for their training classes through trial and error.

We also used mineral powder instead of actual gold to make the class affordable to everyone not just the governors of ancient Japan. With this approach, the process of mending a small plate was finished in just under three hours. The results nevertheless look very similar and let me say amazing to what you will find in traditional methods. This was also done using basic tools that can be found in a Japanese homeware store.

In our class, the tea cups came pre-broken in three pieces saving us from the drama of crashing pottery at home. I made my life harder by accidentally breaking one piece in two and adding extra time to the process. The teacher Hitomi was kind enough to step in and help me with some of the tasks. Broken parts are normally large with smaller pieces being discarded and replaced with the resin.

The process started with filing the sharp edges of the pieces with a file to create grooves between connected broken pieces. These grooves create space for epoxy making making golden lines stand out in the later step.

Once the grooves are created we then mixed the epoxy into a paste and glue pieces together. The residue of epoxy resin on the sides and above the cracks’ surface is removed with a sharp knife. This first round is used to connect the pieces together with a fast-hardening type of epoxy. It felt strangely satisfying to connect the pieces and remove the residue epoxy.

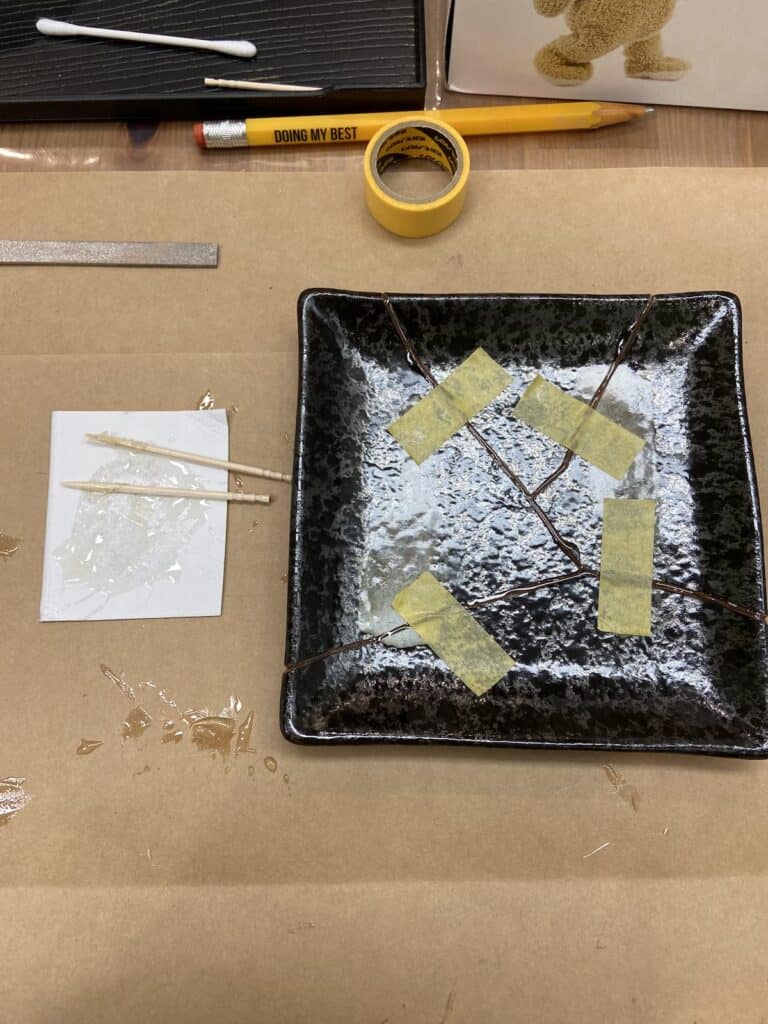

In the next round, the plate is lined with masking tape along the cracks leaving a 1-2 mm gap. Once prepared the groves are filled using a slow hardening epoxy.

The still-sticky epoxy layer is then sprinkled with golden powder giving the plate the iconic Kintsugi look. This is where things can go wrong if I was not careful enough to leave messy fingerprints and epoxy stains. I managed to do a good job as you can see making our Kintsugi instructor proud!

In the final step, the masking tape is removed and the plate is finally cleaned of the residue powder and droplets of epoxy.

While this express process is much faster than the months-long traditional way I got a taste of what it feels like when making something completely broken into a character-filled unique piece. The golden lines added value to unremarkable look-alike square plates from a local store. It is also so because I added my own labour to a mass-produced piece of pottery.

The natural progression from the mini class is what Hitomi called the Dojo, where participants bring their own broken pieces. In these workshops, students get strategy and guidance on how to approach mending their own piece of pottery. In Dojo, traditional methods with plant resin and gold powder can be used as well.

My Learnings From Kintsugi Class

When I was working on my piece I felt calm and focused. This class could easily go on for a few hours without me noticing. I am sure that there are other art forms that give the same sense but I did not expect that with zero knowledge and skill. It is perhaps because Humans are natural problem solvers and Kintsugi by its nature fits right in.

It was also reassuring that this could not be messed up. As Hitomi-San said you can’t break anything while working on it because it is already broken. This is a practical manifestation of “if you are at the bottom the only way is Up”

I also found it funny that when the started lesson Hitome called me Jason. I was called Jake and James but this was new. When I corrected her, I realised to my embarrassment that she was actually addressing me in a Japanese polite way as Jay-san which sounded like Jason.

Would I recommend this class to someone? Yes, 100 per cent because in a short time, you get to experience ancient art and learn about Japanese culture. It is also a practical way to see how broken things turn into something of value with a focused effort and skill.

As an added bonus you walk away with a great-looking piece of pottery that can add character to your home.

I hope you enjoyed reading this and would like to try Kintsugi one day with your own hands. Please subscribe to my monthly newsletters if you would like to stay in touch and learn about my discoveries.